As an Amazon Associate, I earn from qualifying purchases.

MIG and TIG are the main types of welding used for different projects. MIG means metal inert gas while TIG means tungsten inert gas. These welders operate differently and can be used for different projects. Understanding the difference between these welders will help you to know which machine is perfect for your project. This article will illustrate the difference between a mig and tig welder comprehensively.

What is The Difference Between a Mig and Tig Welder?

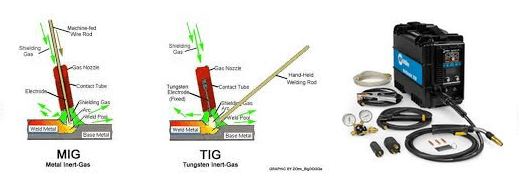

The primary difference between TIG and MIG welder is the welding process. MIG uses a constant feeding wire while TIG makes use of long welding rods and steadily feed them into a weld puddle. They both use an electric arc to create the weld. Learning the MIG welding process is simpler than learning the TIG welding process. This difference makes MIG a good choice for beginners and those who want a welder for simple use.

A MIG welder operates by utilizing a constant feeding spool of welding wire that melts and joins the base and parent metals together. With a MIG, you can weld different materials including aluminum, stainless steel and mild steel. This welder is also perfect for welding thick and thin materials. It can weld materials of up to 40 mm thick.

On the other hand, TIG welding is mainly used for thinner gauge materials. For example, you can use it to make materials like tool boxes and kitchen sinks. You can also use TIG welder for pipe welding and heavier tasks. The thickness when welding with TIG is limited to about 5mm. A TIG welder will require a unit that can output the needed amount of power depending on the project.

The other key difference between MIG and TIG is the versatility. TIG welder is the most versatile unit since it can be used for a variety of projects. It can also be used for welding different types of materials. The shortcoming of TIG is that it’s slow. Although MIG is not very versatile, it’s a bit faster and better for simple home chores.

MIG uses consumable metallic electrode while TIG uses non-consumable tungsten electrode. In the welding process, MIG uses DC while TIC can use both AC and DC. The shield is also a key difference between these welders. MIG is a gas shielded metal arc welding while TIG is a gas shielded tungsten arc welding.

Conclusion

Every project regardless of its size requires the right welder. Although MIG and TIG are popular welders, they have a big difference in their operation and application. You can get quality and clean weld by using the appropriate welder. MIG welders are generally meant for home use while TIG welders are designed for a variety of applications.

Leave a Reply